Website intended for professional users with knowledge or professional experience that enable the use of SmartFlags for their intended purpose.

I declare that:

Website intended for professional users with knowledge or professional experience that enable the use of SmartFlags for their intended purpose.

I declare that:

FULLY AUTOMATED PRODUCTION PROCESS.

0 1

MILLING PRECISION UP TO 2 MICRONS.

0 2

WITHOUT HUMAN POSTPROCESSING.

0 3

GUARANTEED SHAPE REPEATABILITY.

0 4

THE CUSTOMIZED SHAPE OF THE EMERGENCE PROFILE.

0 5

POSSIBILITY OF CHOOSING A RETENTION AREA.

0 6

DESIGN IN ONE GO - PARALLEL ABUTMENT AND CROWN DESIGN AND PRODUCTION.

0 7

Titanium alloy Ti6AI4V ELI (grade 23).

0 8

ANGULATED SCREW-HOLE SOLUTIONS UP TO 28 degrees.

0 9

TWINS™ - CLINICAL AND LABORATORY DUPLICATE IN IDENTICAL SHAPE AND FORM.

10

LIFETIME WARRANTY APOLLO - ABUTMENT&IMPLANT.

11

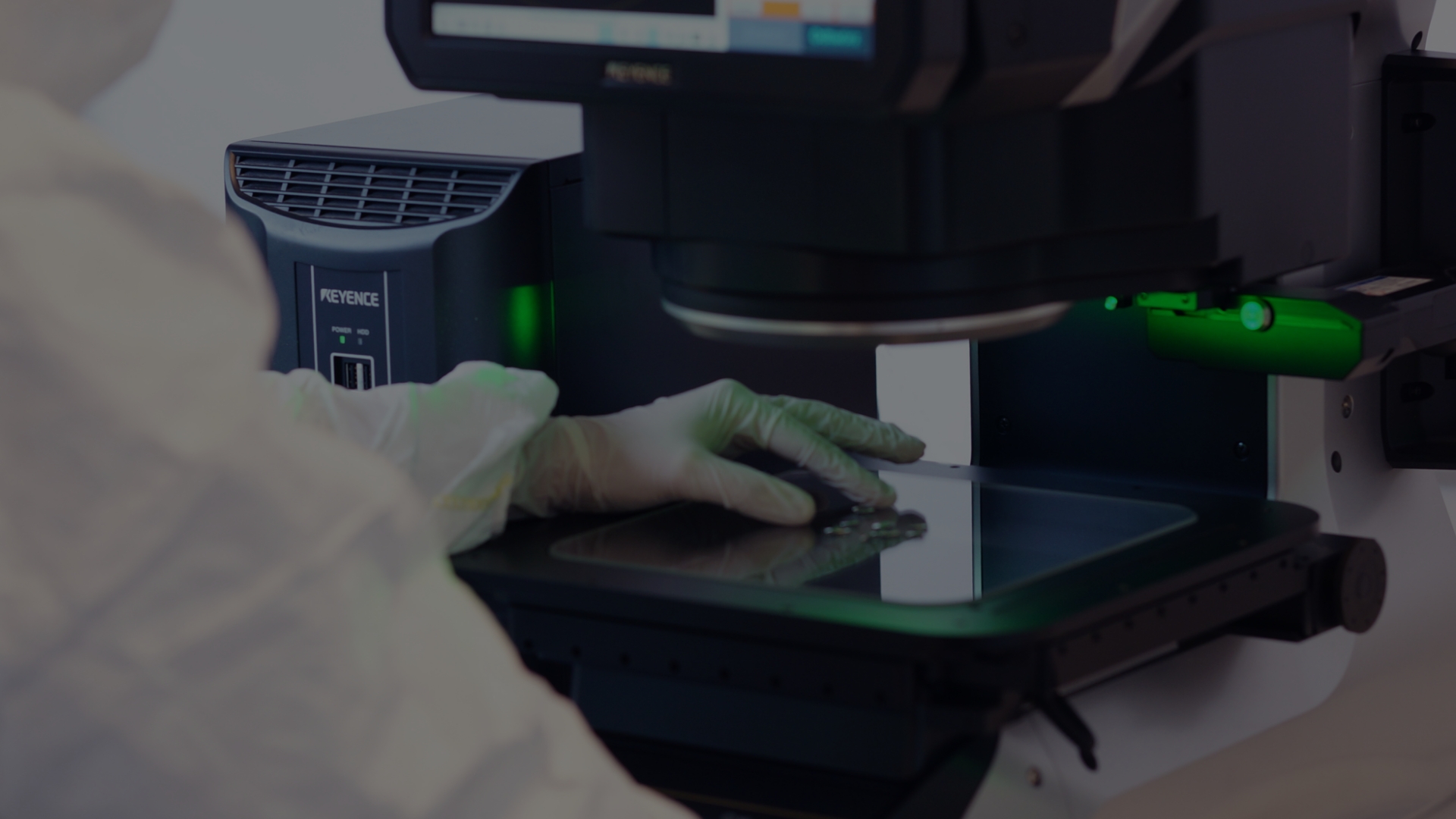

APOLLO IMPLANT COMPONENTS PRODUCTION – modern technologies, professional machine park guarantees precise workmanship of the products of the highest level.

A wide and constantly expanding range of compatible implantological systems.

We take care of every detail, we strictly control the measurements and the quality of workmanship.

Team department: technical support and services.

Quick and easy way of communication, gives the opportunity to edit, analysis and accept the project which optimizes the time in which it will go into production.

Placing orders via the website.

Modern technologies, professional machine park guarantees precise workmanship of the products of the highest level.

LIFETIME WARRANTY – for TITAN™ and GOLD™ abutments.

(If STL files are provided or from the moment the design is accepted by the client).